Alfa-Foam Insulation for Packaging.

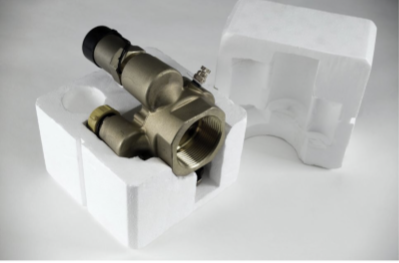

Alfa-Foam gives you the flexibility to create the perfect protection for your product and reduce shipping costs.

Available in a range of densities, types, shape mold or fabricate and it’s all recyclable.

Whether it’s a small or large production run, the control you get with Alfa-Foam makes the best choice. Control

means that your Alfa-Foam packaging and OEM products can be designed to make your operations run smoothly and will

complement your packaging and manufacturing processes. Alfa-Foam components are quick and easy to assemble: no

special handling is required. PAG is the best local vendor you’ve ever worked with offering great customer service,

proven systems and on-time delivery.

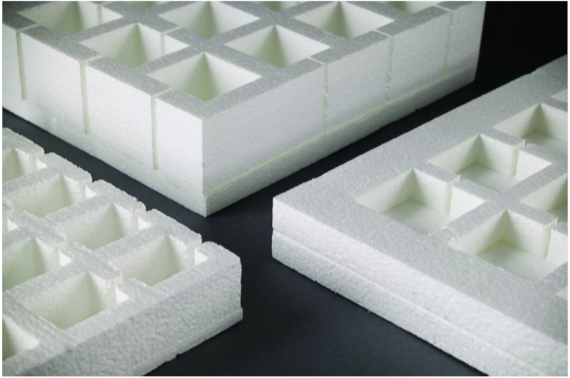

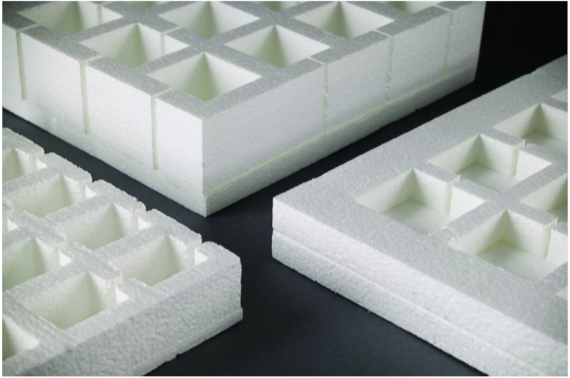

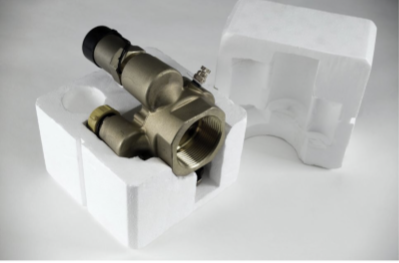

Fabricated Packaging

Alfa-Foam cushion protective packaging is custom fabricated by hot wire cutting with computer aided design (CAD) and if necessary, assembled together to provide a packaging solution specific to your needs. This method is well-suited for lower volume product lines where tooling costs cannot be justified. Yet a custom part is still required. This method allows you maximum protection without the tooling expense associated with custom molded parts. Alfa-Foam is an amazingly strong and versatile material consisting of over 90% air. Alfa-Foam provides protection, cushioning and ecologically safe insulation properties.

Packaging & the Environment

Por Definir

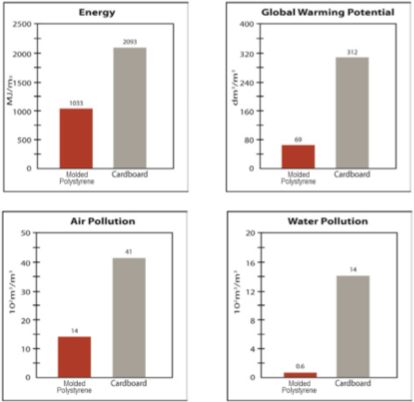

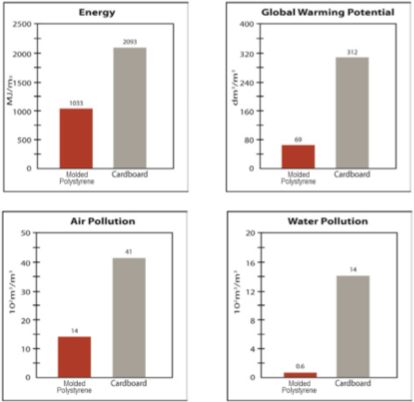

Life Cycle Analysis

A life cycle analysis by InFo Kunststoff e.V. compared molded polystyrene to corrugated cardboard. The

study quantified the energy use, global warming potential, air pollution and water pollution associated

with 1 cubic meter of molded polystyrene packaging or corrugated cardboard packaging.

Results of the study clearly demonstrate the environmental benefits of molded polystyrene packaging when

compared to corrugated cardboard packaging.

Molded Pulp Packaging

Some people have the misconception that Molded Pulp Packaging is a more environmentally friendly choice

than molded polystyrene packaging. Before making a packaging selection based upon misconceptions do your

research and ask the following questions.

- Does cushioning performance from drop tests, vibration tests, temperature control, etc. need to be considered?

- What are the environmental impacts of having to remanufacture goods damaged during shipment?

- Does recycled content of the packaging really equal sustainability?

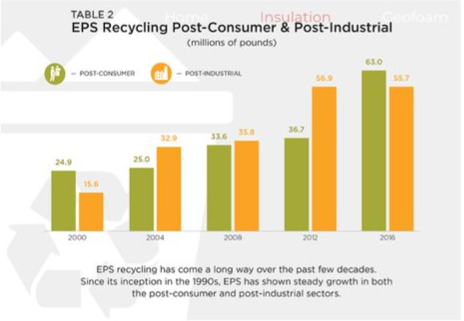

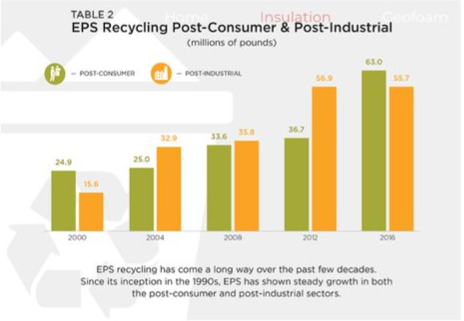

Recycling Rate

Molded polystyrene foam is one of the most heavily debated materials when it comes to recycling. It’s been

recycled successfully by businesses and consumers throughout the U.S. for over 25 years.

As reflected in the graphic, more than 118 million pounds was recycled during a calendar year. This figure

includes 63 million pounds of post-industrial recovery. Post-consumer and post-commercial recycling are

defined as any material that is recycled after its intended end-use – while postindustrial recovery

includes facility scrap that is recycled but never served its intended purpose as a packaging material or

other end-use application.

Chart 2 shows a notable growth for post-consumer and post-commercial recycling. This is supported by a

strong reliance on high volume sources and proves the success of industry recycling technologies,

collaborative collection programs and new end-use markets have continued to broaden recycling

opportunities.

Fabricated Packaging

Alfa-Foam cushion protective packaging is custom fabricated by hot wire cutting with computer aided design (CAD) and if necessary, assembled together to provide a packaging solution specific to your needs. This method is well-suited for lower volume product lines where tooling costs cannot be justified. Yet a custom part is still required. This method allows you maximum protection without the tooling expense associated with custom molded parts. Alfa-Foam is an amazingly strong and versatile material consisting of over 90% air. Alfa-Foam provides protection, cushioning and ecologically safe insulation properties.

Packaging & the Environment

Por definir

Life Cycle Analysis

A life cycle analysis by InFo Kunststoff e.V. compared molded polystyrene to corrugated cardboard. The study

quantified the energy use, global warming potential, air pollution and water pollution associated with 1 cubic

meter of molded polystyrene packaging or corrugated cardboard packaging.

Results of the study clearly demonstrate the environmental benefits of molded polystyrene packaging when

compared to corrugated cardboard packaging.

Molded Pulp Packaging

Some people have the misconception that Molded Pulp Packaging is a more environmentally friendly choice

than molded polystyrene packaging. Before making a packaging selection based upon misconceptions do your

research and ask the following questions.

- Does cushioning performance from drop tests, vibration tests, temperature control, etc. need to be considered?

- What are the environmental impacts of having to remanufacture goods damaged during shipment?

- Does recycled content of the packaging really equal sustainability?

Recycling Rate

Molded polystyrene foam is one of the most heavily debated materials when it comes to recycling. It’s been

recycled successfully by businesses and consumers throughout the U.S. for over 25 years.

As reflected in the graphic, more than 118 million pounds was recycled during a calendar year. This figure

includes 63 million pounds of post-industrial recovery. Post-consumer and post-commercial recycling are defined

as any material that is recycled after its intended end-use – while postindustrial recovery includes facility

scrap that is recycled but never served its intended purpose as a packaging material or other end-use

application.

Chart 2 shows a notable growth for post-consumer and post-commercial recycling. This is supported by a strong

reliance on high volume sources and proves the success of industry recycling technologies, collaborative

collection programs and new end-use markets have continued to broaden recycling opportunities.